If you have ever worked on supply chain in some way, it won't take too long to realize how complex and fragile the system is; numerous variables including environmental condition, labour force, local/global supply-demand seasonality are contributing to make the global supply chain possible, and none of them should be overlooked in order for the distribution network to flow seamlessly, just like human circulatory system without any blood clots.

That is, the whole system relies heavily on certainty and predictability, and it is the foundation of why your delivery packages arrive so fast after ordering, and you can purchase products made on a different continent/island at a local grocery store. I learned the fact in a painful way when I worked as a data scientist for a retail company, and the experience motivated me to dive deeper into the field later: "The Essence of Supply Chain Management".

However, the theory strongly assumes we are living in a normal "perfect" world, and it's obvious that the world has entered an unusual circumstance after the pandemic. Thus, the global supply chain is currently facing serious issues as widely reported, and the system hasn't been functioning well.

Of course, it's a difficult complex problem, but you should be able to get a better sense of the following points after learning more about the news:

- Why is the disruption happening?

- When/How was the modern supply chain originally established, and why are we able to rely so much on the system?

- What should we do moving forward as a consumer (and worker)?

Key takeaways

- Containerization and Just-In-Time (JIT) manufacturing are the biggest inventions in the history of supply chain, and the technology pushed companies to aggressively optimize the efficiency of their day-to-day operations and materially maximize shareholder interests in the context of global capitalism.

- The pandemic surfaced the limitation of the modern JIT-based supply chain, by changing our consumption pattern and forcing workers (e.g., at port, truck, train) to operate under the irregularity.

- This is NOT the first-time disruption we've ever experienced; we repeatedly saw the similar challenges in the past (e.g., due to a natural disaster in Asia), but JIT still plays a crucial role simply because of its efficiency and upstream profit. To make a supply chain resilient in the true sense, the players must accept redundancy while sacrificing efficiency to some degree.

- Future strong supply chains would need a systematic change, such as making a consolidated development effort between nearby ports (e.g., LA and Long Beach in US, Tokyo and Yokohama in Japan). Meanwhile, consumers could possibly change the situation by protesting the harm of mass-consumption trends in our day-to-day decision-making process.

Why is the disruption happening?

After the global pandemic, you might realize that the package deliveries are getting slower, and some groceries gradually become more expensive as time goes by (i.e., inflation). Although it's a combination of multiple factors on a global scale, the disruption process can be broken-down as follows in my understanding:

- COVID-19 has changed our consumption pattern (e.g., more demand for masks and working-from-home equipment), which forced suppliers to produce significantly more/less amount of products and deliver them to unusual destinations under the uncertainty.

- In combination with lockdowns and quarantine policies, operations at big ports in China, the global centre of distribution, became completely irregular and unpredictable.

- Depending on where you live, supply of certain products became unstable accordingly, and their prices went up as a result.

- In order to mitigate the problem and accelerate the turnaround time from production to supply, the global companies started returning their cargo ships back to China as soon as possible. Hence, many "empty" ships are traveling to China (e.g., from the US) so that a return trip can fully eliminate the "non-urgent" inefficiency.

- This workaround, however, caused further shortage of cargo and made a skew of product supply even worse, depending on product category and/or geographical location. There's been a surge of arrival cargo and required workload, and the local labour forces (e.g., operators at a port, truck drivers) cannot handle all of them on time.

- Eventually, many goods result in "staying" at a port after arrival, and they have to wait longer than usual. Of course, it ends up with further slowed supply chains and unstable prices.

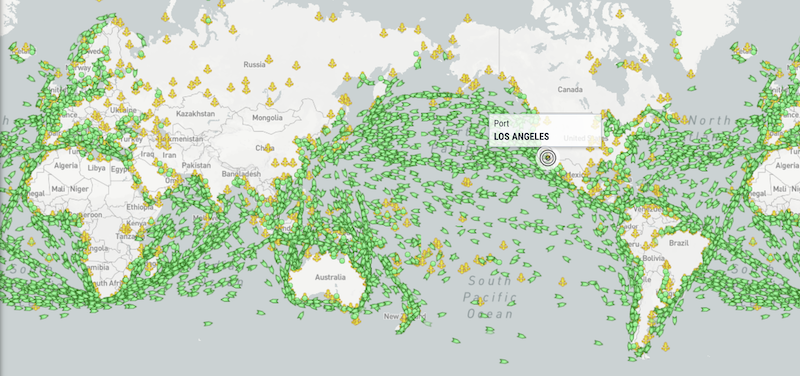

Importantly, the "cargo" here is known as container, and we cannot speak about today's supply chain without understanding the containers as numerous containers are incessantly traveling on the sea:

* Source: MarineTraffic

* Source: MarineTraffic

Containerization has changed the game

Container is a "box" that is packed with goods, and its shape, size, and price are globally standardized. It means that the boxes eliminate the need for loading packages and checking the contents by humans. Alternatively, a transfer process happens without opening a box, and the box can be seamlessly loaded and transferred from oversea cargo to domestic train/truck freight.

Such movement is called containerization, and a famous book "The Box" gives an in-depth explanation of the history. In short, the point is that the container-based standardized shipping process made a supply chain significantly efficient in terms of both money and time.

For capitalists, inventory is the biggest concern in the field of supply chain because the unsold items occupy warehouses without making any immediate profit, while consuming a lot of maintenance/management cost.

Here, since containerization significantly shortened delivery time, the manufacturers became able to minimize the stocks and produce their products on-demand basis; it has become possible to build a final product “after” an order has been made. This is what we call Just-In-Time (JIT) manufacturing, and the concept is based on an assumption that supply and demand of a certain product are generally predictable.

In other words, JIT is not resilient enough against uncertain events. If there is a big, long-lasting problem at one or more points in a supply chain network, the balance between supply and demand can be easily broken. As you noticed, COVID-19 clearly caused such bottlenecks all around the world. Unsurprisingly, since there is no previous experience we can refer to under such a catastrophic event, JIT won't function as seamlessly as it should for a long period of time. Other examples of showing the limitation of JIT include but are not limited to a recent incident at the Suez Canal and huge earthquake and tsunami in Japan in 2011.

How to update "Winner wins more" situation

It's clear that the modern manufacturing system relying on the JIT principle is vulnerable. So, why don't we increase the redundancy of the system e.g., by holding extra stocks at local warehouses?

According to a news report, such discussions have been repeatedly made every time the world faces an unprecedented event, but nothing has fundamentally changed yet. Why? Because the redundancy is not economical. Meaning shareholder interest is always prioritized higher than being prepared for an "unlikely event".

That said, we learned a lot from the global pandemic, and there is a clear need for investing more on solidifying the end-to-end supply chain network. The US government, for example, is discussing extended 24/7 operations at big ports and further financial investment in the facilities. I see this as a vertical scaling approach, which makes a single node of the network stronger by adding extra powers. But the problem here is such an investment could be beneficial ONLY for the big companies that have a huge operational power. For me, it's hard to imagine how small businesses can benefit from the new strategy.

On the other hand, a government could encourage the industry to make a systematic change that cares for multiple stakeholders at once. To give an example, unifying the decentralized operations at nearby ports could be a better way to tackle the disruption, which I refer this as horizontal scaling. Today, there is a situation that multiple ports are located so closely and do operate independently, like Long Beach & LA in the US and Tokyo & Yokohama in Japan, just for some historical and political reasons. Therefore, if they were consolidated and grown together as a single big port along with local communities in these cities, the operations could become "bolder" and more resilient in the long run.

Ultimately, we must be a system thinker who considers not only efficiency but also its social and environmental impact (e.g., local job market relying on the supply chain industry, greenhouse gas emissions from cargo, freight, and warehouses). In that sense, an individual's action plays a key role to derive the next invention of the supply chain. For instance, if you buy more locally, overseas deliveries aren't even needed for that particular product. Or, the minimalistic lifestyle forces you to buy less, and the volume of orders stressing a supply chain should be relaxed. Like any other global problem, there is no easy solution that immediately resolves a root cause, but there are certainly a lot of discussion points we can think of as our own problem.

Share

Categories

See also

- 2021-08-28

- Next "Dot" in Journey: Curiosity-Driven Job Change in Canada (Aug 2021)

- 2021-05-07

- Actionable Insights from Supply Chain Analytics

- 2021-04-04

- The Essence of Supply Chain Management

Last updated: 2022-09-02

Author: Takuya Kitazawa

Takuya Kitazawa is a freelance software developer based in British Columbia, Canada. As a technologist specializing in AI and data-driven solutions, he has worked globally at Big Tech and start-up companies for a decade. At the intersection of tech and society, he is passionate about promoting the ethical use of information technologies through his mentoring, business consultation, and public engagement activities. See CV for more information, or contact at [email protected].

Now Gift a cup of coffeeDisclaimer

- Opinions are my own and do not represent the views of organizations I am/was belonging to.

- I am doing my best to ensure the accuracy and fair use of the information. However, there might be some errors, outdated information, or biased subjective statements because the main purpose of this blog is to jot down my personal thoughts as soon as possible before conducting an extensive investigation. Visitors understand the limitations and rely on any information at their own risk.

- That said, if there is any issue with the content, please contact me so I can take the necessary action.